We are committed to developing, manufacturing and supplying products and Services of unmatched quality.

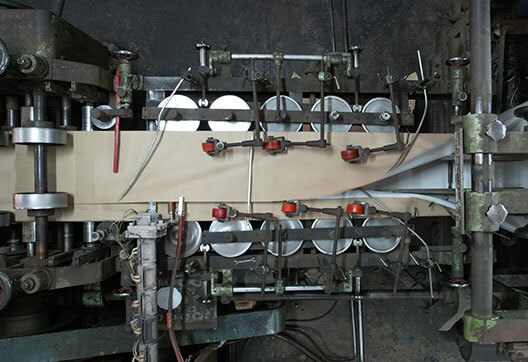

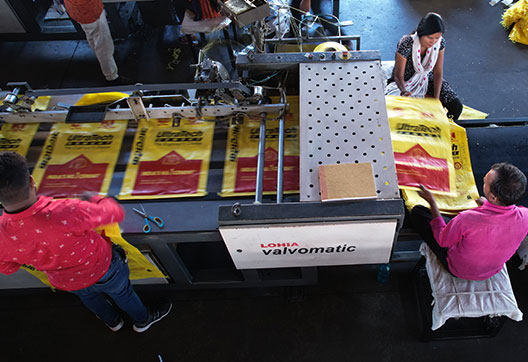

HDPE / PP Woven sacks are becoming popular throughout the World. This is because they are chemically inert & are water repellent & lighter in weight. They possess sufficient strength and can easily be handled. They are competitive in price with other types of bags also. Air-permissible sacks made of HDPE / PP strips are used for packing, Fertilizers, Cement, pesticides, chemicals, oil Seed, food grains, other dry materials & food products.

All our products meet International standards in quality and specifications.

We provide a comprehensive range of Polyethylene and Polypropylene packing bags that conforms to international quality standards. Our products are highly efficient, durable, and reliable. We are also backed by a well-equipped infrastructure, which allows us to maintain a rapid production growth in the competitive market.